|

The shears are blanked out. Strips of steel are cut out in the form of a shears. The cheaper version of the "Blanked" shears are then ground into shape so that it is difficult to sustain precision.Nusharp employ "Fineblanking" technique to shape the blade and punch screw hole at a time. The process is capable of producing sheet metal part with completely smooth edges. It needs no second machining and grinding. This means that not all blanked shears are cheap.

Blanking Process

Single Part

Single Part Transfer:

A single part transfer is a method in which single parts are moved from station to station for blanking and metal forming. The relative dimension of shape and holes is in loose tolerance.

Single Stroke:

Blanking and forming in one die stroke. The relative dimension of shape and holes is in tight tolerance.

|

.jpg) |

|

Progressive

It is a forming process that utilizes a series of stamping stations to perform simultaneous operations on sheet metal. The final metal workpiece is developed as the strip of metal is processed through the stamping die.It's low cost. However, the grain will be cross the blades. This will reduce shearing force of blades, and the blades may snap off.

|

|

Fine- Blanking

Compared with the Fine-Blanking, the Conventional Stamping are found to have about 1/3 shearing edge and their shape is bowed whilst those produced by the Fine-Blanking are found to have100% shearing edge, flat shape and accurate dimensions. Furthermore, in applying the Fine-Blanking Technology, the clearance between the punch and the die is much smaller.

|

|

Advantages

By applying the Fine-Blanking technology, the significant improvement of the component should be obvious. As the components are with good shape, smooth surface and precise size, they can be ready for assembly without any further secondary operations. The productivity is increased the production cycle time and the component cost are significantly reduced.

.jpg) |

|

| 01. Surface produced by conventional method. |

02. Smooth surface produced by Fine-Blanking method. |

|

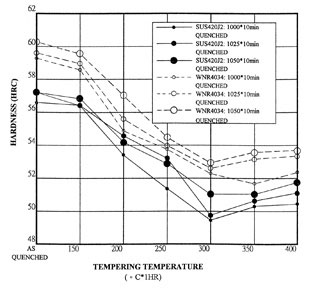

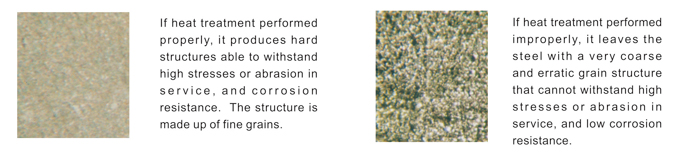

2. Heat Treatment

Heat treating is the operation of heating and cooling a metal in its solid state to change its physical properties. For example, steel can be hardened to resist cutting action and abrasion, or it can be softened to permit machining. With heat treatment internal stresses may be removed, grain size reduced, toughness increased, or a hard surface produced on a ductile interior

.jpg)  .jpg) .jpg)

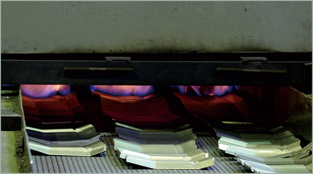

Continuous Heat Treatment

The shears are carried on a conveyor side by side into heating tunnel. Due to its productivity, and cost efficiency, this is the most popular way to harden steel for general application. It minimizes oxygen contact with the parts with a fire curtain.

Vacuum Heat Treatment

.jpg)

For a better quality, the scissors are placed in a vacuum chamber where the oxygen is extracted and heated up.

The key advantage of vacuum heating is making a small grain structure that is tougher than one with large grain structure, so that it makes the shears sharper, more durable and more corrosion resistance.

It is very important to minimize oxygen contact with the parts. If steel comes in contact with oxygen in heat treating, the carbon will dissipate into atmosphere, forming a decarburized layer of steel. This will result in the scissor edges cutting into each other and dulling very fast.

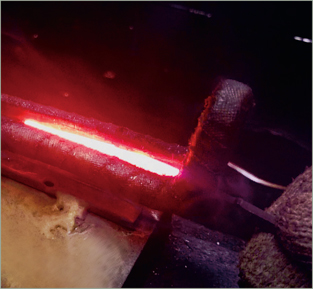

Induction heat treatment

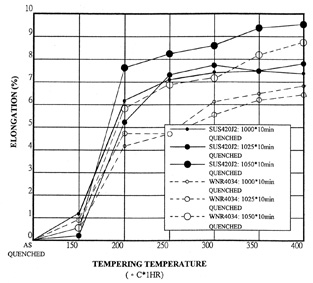

For special application, some of our shears are double heat treated.

For a proper tension between blades, and because the metal behind the cutting edge has the job of transmitting the cutting forces and standing up to the stresses, the shears are first harden to the hardest point of material, which becomes hard and brittle, then subsequently tempered to relieve quenching stresses and to provide a limited but necessary degree of toughness and ductility to protect the part from cracking.

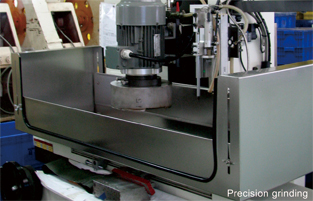

3. Grinding & polish

Grinding means to abrade, to wear away by friction, or to sharpen. In manufacturing it refers to the removal of metal by a rotating abrasive wheel. Wheel action is vaguely similar to a milling cutter, which is considered a multiple cutting point tool. However, a grinding wheel is composed of many small grains bonded together, each one acting as a miniature cutting point. The grinding wheel is considered to have an infinite number of cutting points...

Grinding machines finish parts having cylindrical, flat, or internal surfaces. The surface of the part largely selects the grinding machine. Machines designed for special functions, such as tool grinding or cutting off, are designated according to their operation.

The harden blades then go through several grinding and polish processes.

|

For blanked parts, the blades are put on the rack in row. The operator feeds the rack to sand belt to sand and then polish. For fine blanked parts, it needs only polishing..

|

- Straight grinding in inner blade

For economic reason, the general scissors and shears are straight ground. Comparing with hollow ground shears, it needs more squeezing force in shearing action.

|

Bevel grinding to the backside of blade

There are Flat-ground bevel and Hollow-ground bevel. In shearing action, the shears with hollow-ground bevel is with less force. The bevel angle, small angle less force, larger angle more force is required in closing a shears. But, when determining the bevel angle, we have to consider the thickness of blade. The thinner blade with larger angle will scarify the clamping force of blades through the entire length of cut or else tearing may occur rather than being cut.

Cutting edge grinding

The cutting angle, shears may have very thin or thick blade with different cutting angle.Both blades can be cutting blades in the same or different angle, or one of them is anvil in any combination. Most are designed for specific uses; preferences are determined by the end user.

Besides above mentioned that various cutting angles with different applications, the shears also distinguish between straight blade and curved blade.The curved blades offer consistent closing angel to reduce a force that pushes the work piece toward the tips. It can be one curve or a combination of different curves.

Inside chamfer, the shears designed for garden use or for any other rough cuts may cross cut its blades due to the cross force. To avoid a cross cut and chipping the blade, an inside chamfer is required at the tip of cutting edge.

Polish, to easy cut and to maximize the stainless feature, the surface should be highly buffed. After grinding, the grit leaves a rough surface which looks like a ragged groove under microscope. Moisture, or other foreign particle etc., can be trapped in the cracks and the steel could get rusty.

Notch, when cutting a tougher or round shape work piece, it is best to place the work piece closest possible to fulcrum. Tougher the work piece, harder the force will push it out of position.The notch can hold the work piece and reduce the closing angle of shears in turn with less squeezing force required.

Serrations .are fine lines or teeth ground into the edge of one blade.The serration holds the work piece, keeping it from being pushed forward.

.jpg)

Hollow grinding in inner blade

The high quality shears made by Nusharp are hollow ground. The advantage of hollow ground shear is to reduce the friction resistance and prevent the material jammed in shearing action. This is not only increasing the productivities, but also reducing operator fatigue.

Nusharp designed their own machine, which can be adjusted to a desired hollow depth, and process a consistent hollow side of blades, and offer a consistent quality.

Nusharp is also able to grind spiral hollow blades. This can vary the clearance angle on the cutting edge and compensate the squeezing force while the cutting point is moving forward to tips of shears.

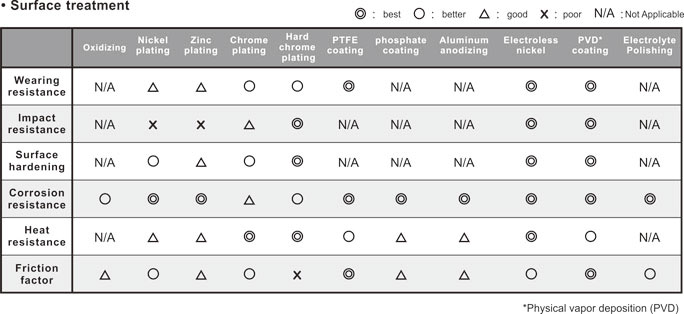

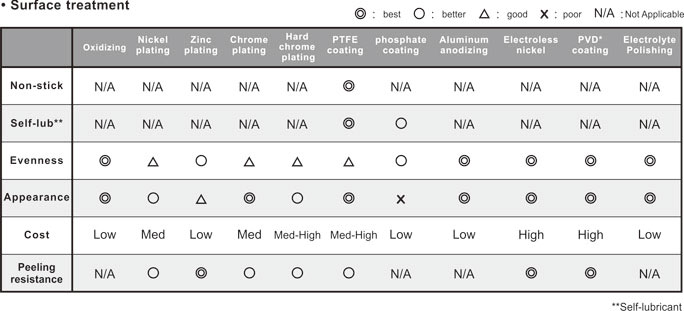

4. Surface treatment

The processes of surface treatments, more formally surface engineering, tailor the surfaces of engineering materials to:

• Control friction and wear

• Improve corrosion resistance

• Vary appearance, e.g., color and roughness

• Change physical property, e.g., conductivity, resistivity, and reflection

Ultimately, the functions and/or service lives of the materials can be improved.

Other surface finishing

Sandblasting is used to clean, deburr, or etch a surface; the effect is similar to that of using sandpaper, but provides a more even finish with no problems at corners or crannies.

Tumbling finishing is used to burnish, deburr, clean, radius, de-flash, descale, remove rust, polish, brighten, prepare parts for further finishing, and break off die cast runners.

|